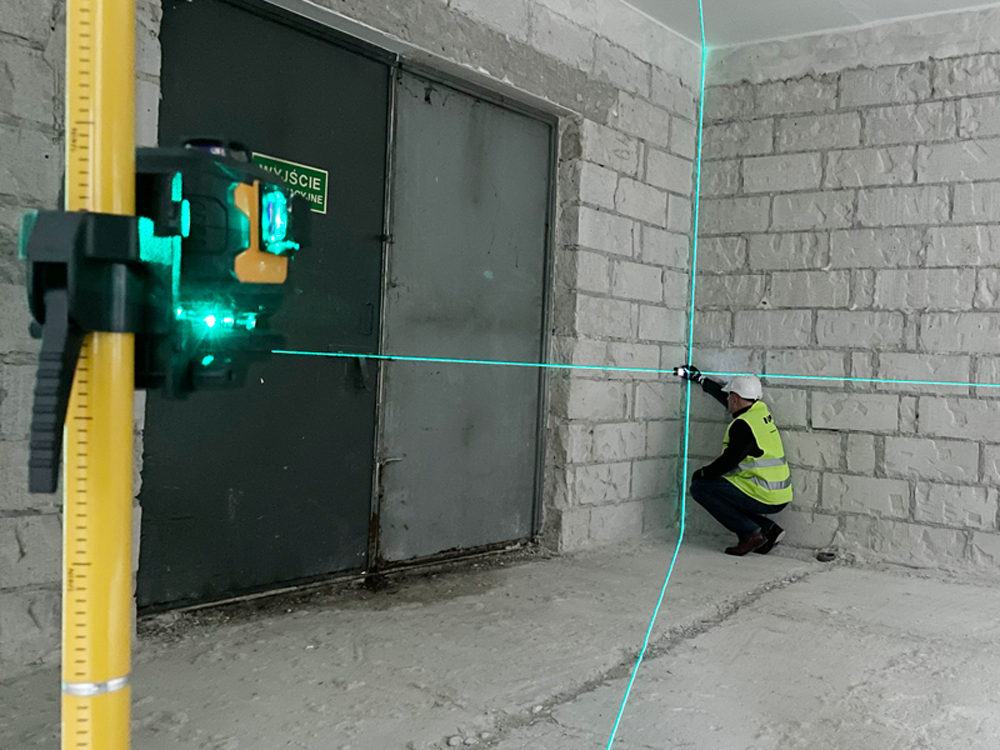

The construction lasers commonly known as “laser crossliners” are measuring instruments used to set references in the form of laser lines. In practice, when projected on the wall, they create the reference for works in horizontal, vertical or sloping planes. They have achieved popularity thanks to – among other features – intuitive operation and high accuracy of performed works. Laser crossliners are easy to use and their operation does not require any special qualifications. The tools of this type effectively replace the classic solutions such as water level, level, rope and pegs. Their unique features allow savings in materials, reduction in the costs of work because they can be operated by one person. The accuracy of measurements is such that there is no need for corrections. Such features provide for the competitive advantage in the market. When correctly operated, regularly calibrated and serviced, they are the guarantee of smooth operation and security of correct measurements for years.

Laser planes

There are two groups of lasers in the construction market:

- Laser crossliners with a beam displayed at a narrow angle

Such models are the cheapest ones and they offer the most basic solutions. Laser lines are displayed only before the device, in front of it. They are limited to two lines: vertical and horizontal ones. The display angle of a beam is the most often available in the range of 90°-120°, and therefore all works have to be performed in front of the device. When it is necessary to use the reference in another direction, the device has to be repositioned. Undoubtedly, it has a negative influence on the accuracy of measurements. The lasers of such type are recommended for simple and basic construction and assembly works over small distances. - 360° multi-plane laser crossliners

Such instruments offer full-plane laser coverage in the range of 360° for each plane. Laser crossliners available in the market can generate:

- 2 planes: 1 horizontal and 1 vertical,

- 3 planes: 1 horizontal and 2 vertical,

- 4 planes: 2 horizontal and 2 vertical.

The selection of the number of beams depends on the nature of works and the degree of their complexity. The higher number of beams, the better scope of control of construction works. There is no necessity to reposition the device if the measurements are to be made in different directions. What’s very important for planes displayed horizontally is that the laser crossliner has the laser head at the bottom. It is a very practical solution because the laser beam is generated at a very low level. When placed on the floor, it helps controlling the level of the plane, and the line projected on the wall allows tiling, performing an assembly from the so-called “zero” level (from the first row).

A very important element which should be considered when deciding on the measuring instruments includes the external heads of the laser crossliner. When compared to the devices with the head integrated in them (the lasers having the shape of a Thermos flask), the models with external heads offer the display of beams without any limitations.

360° multi-plane lasers are a perfect solution for all those who look for a universal and accurate device for professional applications.

Compensator

Depending on the type of performed constructions works, different types of measuring instruments are recommended.

- For the general building and construction works performed in horizontal and/or vertical planes, inside the buildings, over a distance up to 140 m, a dedicated solution includes a laser crossliner with a magnetic compensator. The lasers which are the best for such works are the multi-plane ones offering full-plane laser coverage in the range of 360°.

- For the works performed both inside and outside the buildings, over a distance up to 140 m, the laser crossliner is once again a good choice. However, in this case, the instrument has to be equipped with an electronic compensator which – when compared with the classic magnetic one – can cope with ground vibrations and thus ensures the stability of the beam. In addition, the laser should have the possibility of operation with a laser sensor It is recommended to additionally buy a laser levelling stave which supports the levelling works outside.

- For the works performed outside, the works in the scope of general construction, paving, installation, earthworks and road works, over a distance longer than 140 m, it is necessary to consider the purchase of a device other than a laser crossliner. A rotation laser,g. from the series of Nivel System NL500/700, will be the best choice. Rotation lasers allows the works over large distances, even from 500 to 700 m.

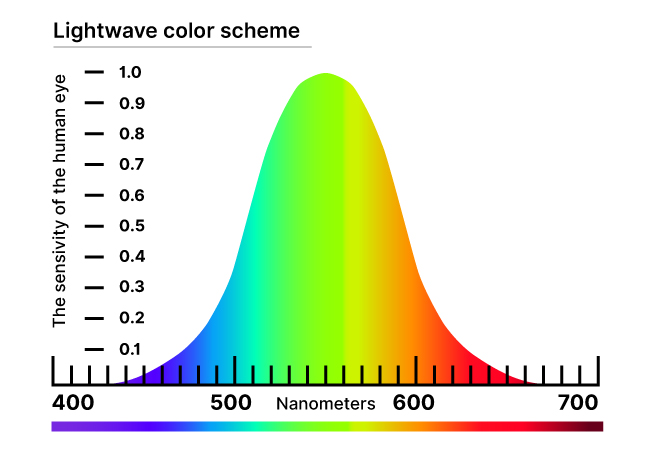

Laser beam colour

The colour of a laser beam is of great significance. It influences – among others – the visibility of the laser beam. The following chart perfectly shows the differences.

- red beam – performs well for works in dark rooms, with poor light, over smaller distances. The lasers offering this beam colour are an economic option as they are the cheapest ones.

- green beam – the visibility of this beam is 4 times better than that of the red one. It is perfect for works in bright and sunlit rooms, over long distances. In such conditions, the visibility of the red beam is low or none.

- blue beam – in terms of visibility, it is similar to the green one. However, its advantage is such that its light is more clear, which means that laser lines are not overexposed. It is significant in small rooms or when working with light-reflecting materials, such as polished tiles. Reflection of the blue beam does not strain your eyes, and the long hours of works with the laser become more comfortable. Blue beam is also slightly narrower than red or green beams. It is a perfect choice for those who require the utmost accuracy. At present, it is the best option guaranteeing the works in both well-lit and sun-lit rooms and works over longer distances.

The selection of the beam colour is important only for works inside the buildings. For the works outside, neither of the laser beams is visible and therefore it is necessary to use the laser sensor. It results from the safety requirements. For the laser light has to be weaker than the natural light. Otherwise, it may damage the eyesight. The cooperation of the sensor with a laser crossliner requires that the latter has the PULSE mode.

There are two types of laser sensors:

- manual sensor

manual indications – 3 positions: raise the sensor, lower the sensor, zero indication (level). The sensor assists in finding the laser beam at long distances, When combined with a laser levelling stave, it enables the performance of classic levelling. - digital sensor

digital indications – the differences in heights are shown as numbers on the display, the readings are in millimetres. When combined with a laser levelling stave, it enables the performance of classic levelling.

Power supply

The power supply for laser crossliners is another important element to be considered when deciding on the measuring instruments. There are two types of power supply:

- from non-rechargeable battery – very popular but expensive. In addition, it is not eco-friendly.

- from rechargeable battery – less popular but more efficient. When this type of power supply is selected, it is recommended to decide on lithium-ion (Li-ion) cells as they are the most efficient. They can be recharged at any moment as they do not have the memory effect. It is recommended to decide on the device which has the possibility of charging the battery during the operation of the laser. It is possible in two options. The first one occurs through the use of external charger with additional rechargeable battery. And the second one consists in direct charging of the battery, without connecting the charger directly to the laser. The source of power supply for all Nivel System laser crossliners is a rechargeable battery, which is the guarantee of the continuity of their operation.

Price

Our decision is often influenced by the price. However, in the case of measuring instruments, the most important criterion should be the measurement accuracy. It often happens that cheap equipment is characterised with low quality, low-level accuracy of measurements. When the decision is based only on offered low prices, we need to consider the risk of interruptions in works, costly corrections, damage to materials, or simply a poor opinion or loss of reliability in the market.

Therefore, we advise that you make reasonable decisions, especially in the scope of measuring instruments. When you make a decision about the purchase:

- Do not be influenced by a low price – select a proven and safe brand and gain competitive advantage

- Select a reliable and proven equipment – read opinions, verify the supplier

- Remember about maintenance service – as the equipment may be damaged. Regardless of the type, brand, price or design of a laser, it is necessary to check, calibrate and service it regularly. Select a supplier with national, local service centre. Do not invest in equipment from uncertain sources, even if the price is low. Such suppliers probably do not offer maintenance services. It may also turn out that calibration or even a simple repair is not possible due to the laser design. In addition, there is no certainty that the offered parameters are kept as such products do not have the required certificates.

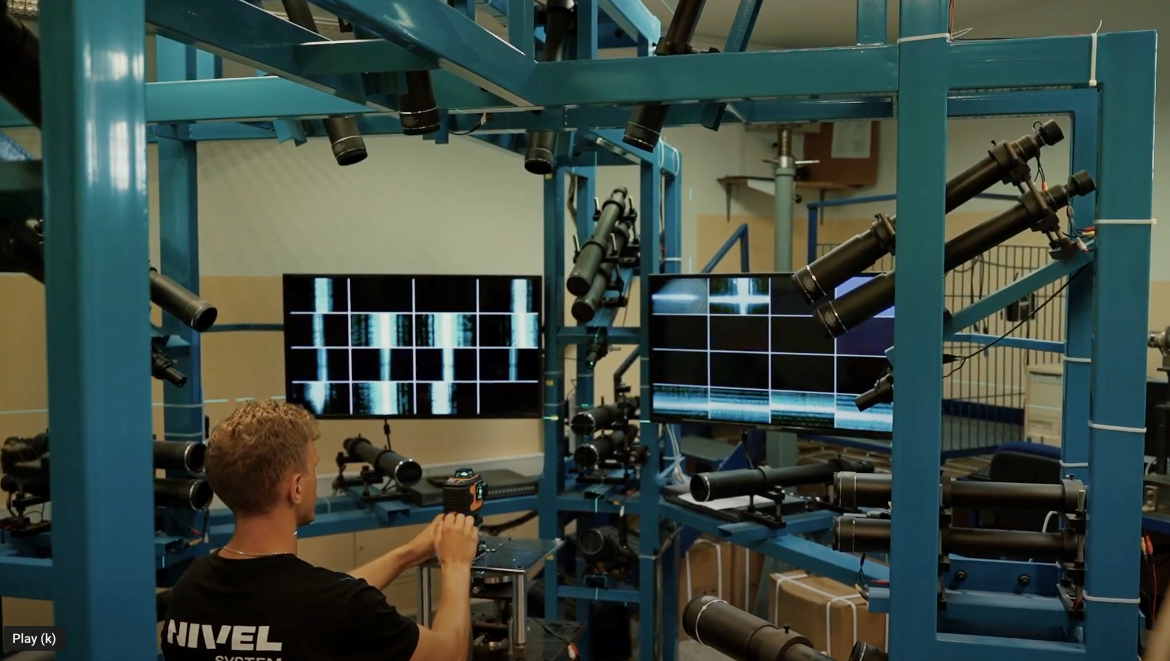

Why is 3D calibration so important and why is it worth paying for such a service?

Incorrect readings and indications of measuring instruments expose their users to costly corrections and the loss of investors’ trust. Therefore, when the equipment is used, it should be regularly inspected, checked for correct measurements, regularly calibrated, and in the event of any problems – serviced. Full calibration is required especially for multi-plane lasers. It consists not only in setting the horizontal and vertical lines but – first of all – in positioning the planes in relation to each other, It is a complex process which requires specialist equipment, such as Octopus Prime 3D collimator, know-how and experience. It is also recommended to verify whether the equipment supplier offers maintenance services including full 3D - 360° laser calibration.

Accessories

We often do not pay any attention to standard accessories provided with the equipment but it is one of the most important arguments when deciding on a laser crossliner. It happens very often that the laser alone, without basic accessories, is just useless. Additional accessories effectively expand the range of functions offered by the equipment. Therefore, it is worth taking care that the standard accessories of a laser crossliner include the following:

- A safe carrying case to ensure safety and facilitate mobility

- A laser is mounted at different heights and therefore it is recommended to have a multi-adapter which makes it possible to mount the equipment on a profile, hook or with the use of the magnet

- While working with the lower plane, it is important to have floor targets to level the floors. The laser beam projected on the targets indicates the assumed level.

- While working with the lower beam to accurately set the first row of tiles on the wall (the so-called “zero” line), a laser lift is irreplaceable.

- All types of structures are installed according to laser lines. The problem appears when there is no possibility of projecting such lines on the wall, for example. In such a case, it is necessary to have the construction target with a scale. It allows quick adjustment and installation of a construction element in compliance with the design.

- The laser functions can be managed from one device – choose the proven Bluetooth wireless communication. In comparison with infrared remote controllers, Bluetooth performs better on construction sites. It allows the work over longer distances, and the obstacles do not limit the communication. The operation of a laser crossliner with the use of a mobile application facilitates and simplifies the works.

- Select the devices powered by rechargeable (Li-ion) battery with the possibility of laser-independent charging. It guarantees that the laser is not damaged during its charging, e.g. through using the wrong charger. Such power supply ensures that there are no interruptions in the operation and if there are any problems with the battery, it can be easily replaced.

- A laser should have built-in (1/4”) thread to mount it on a tripod or an extension pole. For the works which require frequent changes of settings and a spot from which measurements are made, e.g. levelling up to 1.8 m, a tripod is a recommended accessory. In the case of static works, inside a building, when the measurements at heights exceeding 1.8 m are required, use a pole. In both situations, it is possible to accurately and precisely set the height and direction of laser beams.

- A laser sensor – used to work over longer distances (exceeding 30 m). It is also necessary for outside works where the laser beam is not visible.

- A laser levelling stave – very useful for classic levelling, i.e. setting the differences at heights.

Deciding on the producer. Why is it worth choosing the Nivel System brand?

- Nivel System to polska marka oferująca wysokiej jakości instrumenty i akcesoria pomiarowe. Naszą działalność, której początki miały miejsce w 2003 roku, opieramy na nabytym doświadczeniu w zakresie opracowywania, produkcji, dostaw oraz serwisu sprzętu pomiarowego.

- Inspiracje przy tworzeniu i produkcji czerpiemy głównie od naszych klientów wykorzystując własne patenty. Nie wahamy się sięgać po nowe, innowacyjne pomysły, wdrażamy z powodzeniem pionierskie rozwiązania jak np. niebieski laser czy 4-płasczyznowe lasery krzyżowe z elektronicznym kompensatorem.

- Nasze produkty są wyposażone w najwyższej jakości komponenty wiodących dostawców z całego świata, dzięki czemu produkty Nivel System odpowiadają̨ najnowszym trendom i oczekiwaniom Klientów.

- Dzięki rozbudowanej sieci dystrybutorów w całej Europie, produkty Nivel System są znane i dostępne w wielu popularnych sklepach z narzędziami i materiałami budowlanymi, a także w specjalistycznych sklepach ze sprzętem pomiarowym. Klienci mogą testować i wybierać sprzęt z bogatej gamy oferty, dostosowując ją do własnych potrzeb i możliwości.

- Zapewniamy wsparcie za pośrednictwem naszych regionalnych przedstawicieli, posiadamy jedną z najnowocześniejszych platform diagnostycznych dla laserów budowlanych w serwisie - Octopus Prime 3D. Nasze instrumenty przed sprzedażą̨ są sprawdzane i kalibrowane (posiadają indywidulany certyfikat przypisany do urządzenia), a w przypadku jakichkolwiek problemów w użytkowaniu zapewniamy szybki i skuteczny serwis.

Nivel System laser crossliners – technical parameters

| CL2R | CL2G | CL2B | CL3R | CL3G | CL3B | CL4R | CL4G | CL4B | CL4D-G | CL4D-B |

Laser beam colour | red | green | blue | red | green | blue | red | green | blue | green | blue |

Accuracy | ±2.0mm/10m | ±1.0 mm/10m | |||||||||

Range | 30 m (70 m with a sensor) | ||||||||||

Compensator | magnetic | electronic | |||||||||

Sloping planes | Yes | ||||||||||

Planes | 2 (1 x horizontal, 1 x vertical) | 3 (1 x horizontal, 2 x vertical) | 4 (2 x horizontal, 2 x vertical) | ||||||||

Lower plane | Yes | ||||||||||

Pulse mode | Yes, cooperation with laser sensors | ||||||||||

Bluetooth | Yes (+ application for iOS and Android) | ||||||||||

Powered by rechargeable battery | Li-ion | Li-ion (2 pcs.) | |||||||||

Battery charging | laser-independent | ||||||||||

Waterproof rating | IP54 | ||||||||||

Accessories - standard | carrying case, laser multi-adapter, floor targets (2 pcs.), laser lift, construction target, rechargeable batteries (CL4D - 2 pcs.), charger, laser glasses | ||||||||||

Accessories - option | tripod with elevator (SJJ-M1 EX), extension pole (LP-36), manual sensor (CLS-3), digital sensor (RD800 DIGITAL), laser levelling stave (LS-24) | ||||||||||

Still in doubt? Ask an expert

The data from the form will be used only to discuss the above inquiry. By registering, you confirm that you accept our privacy policy.